Ukunemba kwezimoto ifektri yeshubhu ekhanyayo

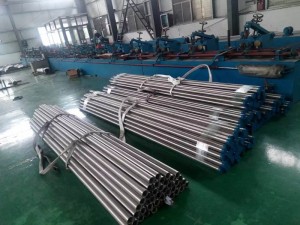

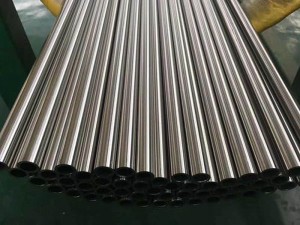

Ishubhu elikhanyayo eliqondile liwuhlobo lwempahla yeshubhu yensimbi enembe kakhulu ngemva komdwebo omuhle noma ukugoqeka okubandayo. Ngenxa yokuthi akukho ungqimba lwe-oxide ezindongeni zangaphakathi nangaphandle zepayipi elikhanyayo ngokunemba, akukho ukuvuza ngaphansi kwengcindezi ephezulu, ukunemba okuphezulu, ukuphela okuphezulu, akukho deformation ekugobeni okubandayo, ukuvutha, ukucaba futhi akukho mifantu, isetshenziswa ikakhulukazi ukukhiqiza imikhiqizo. wezingxenye zomoya noma ze-hydraulic, njengesilinda somoya noma isilinda sikawoyela, esingaba ipayipi elingenamthungo noma ipayipi elishiselwe. Ukwakheka kwamakhemikhali kweshubhu elikhanyayo elinembile lihlanganisa i-carbon C, i-silicon Si, i-manganese Mn, i-sulphur s, i-phosphorus P ne-chromium CR. Insimbi yekhwalithi ephezulu ye-carbon steel, i- finish rolling, i-non-oxidizing bright heat treatment (NBK state), ukuhlolwa okungonakali, ukuxubha kanye nokugeza okunomfutho ophezulu wepayipi lensimbi odongeni lwangaphakathi olusebenzisa izinto ezikhethekile, ukwelashwa kwe-antirust ngowoyela we-antirust epayipini lensimbi, nokwelashwa okungangenwa izintuli ngamakhava. emikhawulweni yomibili. Izindonga zangaphakathi nangaphandle zepayipi lensimbi zinembile kakhulu futhi ziphelile. Ngemuva kokwelashwa kokushisa, ipayipi yensimbi ayinakho ungqimba lwe-oxide nokuhlanzeka okuphezulu kodonga lwangaphakathi. Ipayipi lensimbi lithwala ukucindezela okukhulu, aliguquki ngesikhathi sokugoba okubandayo, futhi alinayo imifantu ngesikhathi sokuvutha kanye nokucaba. Ipayipi lensimbi elinembile lingacutshungulwa ukuze kube nokuguquguquka okuhlukahlukene okuyinkimbinkimbi kanye nomshini. Umbala wepayipi lensimbi: omhlophe ngokugqamile, nokucwebezela kwensimbi ephezulu. Izesekeli zezimoto nezemishini zinezidingo eziphezulu zokunemba nokuqedwa kwamapayipi ensimbi. Abasebenzisi bepayipi lensimbi enembile akubona kuphela abasebenzisi abanezidingo eziphezulu zokunemba nokuqeda. Ngenxa yokuthi ipayipi elikhanyayo elinembayo linokunemba okuphezulu futhi ukubekezelelana kungagcinwa ezintanjeni ezingu-2-8, abasebenzisi abaningi bomshini baguqula kancane kancane ipayipi lensimbi engenamthungo noma insimbi eyindilinga ibe ipayipi elikhanyayo ngokunemba ukuze kongiwe ukulahlekelwa kwabasebenzi, impahla kanye nesikhathi.

Isakhiwo se-martensite sitholakala ngokucisha ishubhu elikhanyayo ngokunemba futhi lifakwe ebangeni lokushisa elingu-450 ~ 600 ℃; Noma ngemva kokushisa ku-650 ℃, dlula ku-350 ~ 600 ℃ ngesilinganiso sokupholisa esinensayo; Noma ngemva kokushisa ku-650 ℃ nokushisa isikhathi eside ebangeni lokushisa lika-350 ~ 650 ℃, ishubhu elikhanyayo elinembile lizokhiqiza i-embrittlement. Uma i-embrittled 20# precision steel tube ifudunyezwa kabusha ibe ngu-650 ℃ bese ipholiswa ngokushesha, ukuqina bungabuyiselwa. Ngakho-ke, ibizwa nangokuthi% 26ldquo; Ukufutheka okubuyisela emuva%26rdquo; I-brittleness ye-temperature ephezulu yokushisa ikhombisa ukwanda kokuqina kokuqina kwezinga lokushisa lokunemba kweshubhu elikhanyayo. Amazinga okushisa aphezulu anciphisa ukuqina. Ukuzwela ngokuvamile kunqunywa umehluko phakathi kwezinga lokushisa lokushintsha kwe-ductile brittle esimweni sokuqina kanye ne-brittle state (% 26delta; T) Ukubonisa. Uma kuqine kakhulu ukuqina kwezinga lokushisa eliphezulu, kuyanda ingxenye yokuphuka kwe-intergranular ekuqhekekeni kweshubhu elikhanyayo ngokunemba.

Imithelela yama-elementi ku-brittleness yokufudumala kwezinga lokushisa eliphezulu ngokunemba kweshubhu elikhanyayo ihlukaniswe yaba: (1) izakhi zokungcola ezibangela ukushisa okuphezulu kwezinga lokushisa elithambile leshubhu elikhanyayo elinembile, njenge-phosphorus, ithini, i-antimony, njll(2) Izakhi zengxubevange ezikhuthazayo noma ezihamba kancane. phansi ukuqina kwezinga lokushisa eliphakeme ngezindlela ezahlukene namadigri. I-Chromium, i-manganese, i-nickel ne-silicon idlala indima yokuthuthukisa, kuyilapho i-molybdenum, i-tungsten ne-titanium idlala indima yokubambezeleka. Ikhabhoni nayo idlala indima ebalulekile. Ukunemba okujwayelekile kwekhabhoni amashubhu akhanyayo awafinyeleli ekushiseni okuphezulu kwezinga lokushisa. Insimbi ye-alloy kanambambili noma yama-multicomponent equkethe i-chromium, i-manganese, i-nickel ne-silicon izwela kakhulu, futhi ukuzwela kwayo kuyahlukahluka kuye ngohlobo nokuqukethwe kwezakhi ze-alloy.

Ukuzwela kwesakhiwo sangempela seshubhu elikhanyayo eliqondile elicijile kuya ku-temperature brittleness yensimbi kuhluke kakhulu. Isakhiwo sokushisa esiphezulu se-Martensite sizwela kakhulu emazingeni okushisa aphezulu, isakhiwo se-bainite esiphezulu sezinga lokushisa singesesibili, futhi isakhiwo se-pearlite sincane kakhulu.

Ingqikithi yokushisa okuphezulu kokushisa kwe-brittleness yeshubhu elikhanyayo ngokunemba ngokuvamile ibhekwa njengomphumela wokuhlukaniswa kwezakhi ezingcolile ezifana ne-phosphorus, ithini, i-antimony ne-arsenic emngceleni wokuqala wokusanhlamvu we-austenite, okuholela embrittlement yomngcele wokusanhlamvu. Ama-elementi e-alloy afana ne-manganese, i-nickel ne-chromium ahlukaniswa ngokuhlanganyela nezinto ezingenhla zokungcola emngceleni wokusanhlamvu, okuthuthukisa ukunothisa izakhi zokungcola futhi kuqinise ukugqwala. Ngokuphambene nalokho, i-molybdenum inokusebenzelana okuqinile ne-phosphorus nezinye izakhi zokungcola, ezingakhiqiza isigaba semvula kukristalu futhi ivimbele ukuhlukaniswa komngcele wokusanhlamvu we-phosphorus, okunganciphisa ukuhwalala kokushisa okuphezulu. Izakhi zomhlaba ezingavamile nazo zinomthelela ofanayo njenge-molybdenum. I-Titanium ingaphromotha ngempumelelo kakhulu ukuna kwe-phosphorus nezinye izici zokungcola kukristalu, ukuze yenze buthaka ukuhlukaniswa komngcele wezinhlamvu zezinto ezingcolile futhi yehlise ijubane lokuqina lokushisa eliphezulu.

Izinyathelo zokunciphisa izinga lokushisa eliphezulu elithambile brittleness of ukunemba amashubhu agqamile zimi kanje: (1) ngemva izinga lokushisa eliphezulu, ukupholisa uwoyela noma amanzi Ukupholisa ngokushesha kusetshenziswa ukuvimbela ukuhlukaniswa izakhi ukungcola emngceleni okusanhlamvu (2) Lapho molybdenum. okuqukethwe kwensimbi kukhula ku-0.7%, ukuthambekela kwe-embrittlement kokushisa okuphezulu kokushisa kuyancipha kakhulu. Ngalé kwalo mkhawulo, amashubhu ensimbi angama-20# okunemba enza ama-carbides akhethekile anothe nge-molybdenum, okuqukethwe kwe-molybdenum ku-matrix kuncipha, futhi ukuthambekela kokuqina kwamashubhu agqamile okunembayo kuyenyuka (3) Yehlisa 20# okuqukethwe kwezinto ezingcolile epayipini lensimbi elinembayo (4) ) Kunzima ukuvimbela i-embrittlement yezingxenye ezisebenza endaweni ye-embrittlement yokushisa ephezulu isikhathi eside ngokungeza i-molybdenum kuphela. Kuphela ngokunciphisa okuqukethwe kwesici sokungcola okungu-20# epayipini lensimbi elinembayo, ukuthuthukisa ukuhlanzeka kwepayipi elikhanyayo elinembayo, kulekelelwa ingxubevange eyinhlanganisela ye-aluminium nezinto zomhlaba eziyivelakancane, kungavinjelwa ngempumelelo ukufudumala kwezinga lokushisa eliphezulu.