Ukunemba odongeni oluncane olukhanyayo ifektri yeshubhu

Ipayipi lensimbi elingenamthungo elishisayo lihlukaniswe ipayipi lensimbi elijwayelekile, ipayipi lensimbi elicindezelayo eliphansi neliphakathi, ipayipi lensimbi elinomfutho ophakeme, ipayipi lensimbi yengxubevange, ipayipi lensimbi engagqwali, ipayipi lokuqhekeka lika-petroleum, ipayipi lensimbi ye-geological kanye namanye amapayipi ensimbi.

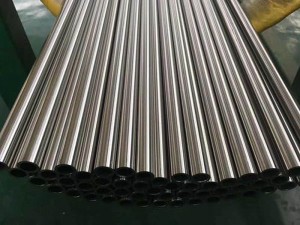

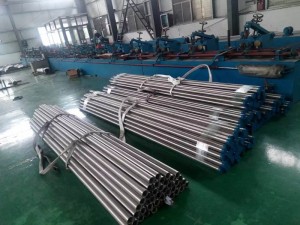

Ipayipi lensimbi elibandayo eligoqeke (elidwetshiwe) elingenamthungo lihlanganisa ipayipi lensimbi elinezindonga ezincane elinesikhabhoni, ipayipi lensimbi elinezindonga ezincane, ipayipi lensimbi engenasici, ipayipi lensimbi elinezindonga ezincane ezingenasici kanye nepayipi lensimbi elimise okukhethekile ngaphezu kwepayipi elivamile lensimbi, ipayipi lensimbi elinomfutho ophansi nophakathi, ipayipi lensimbi elinomfutho ophakeme, ipayipi lensimbi yengxubevange, ipayipi lokuqhekeka kwe-petroleum namanye amapayipi ensimbi. Ububanzi bangaphandle bepayipi elingenamthungo eligoqwe elishisayo ngokuvamile bukhulu kuno-32mm futhi ukujiya kodonga kungu-2.5-75mm. Ububanzi bepayipi lensimbi elingenamthungo eligoqiwe ngokubanda lingaba ngu-6mm futhi ukujiya kodonga bungafika ku-0.25mm. Ububanzi bangaphandle bepayipi elinezindonga ezincane bungaba ngu-5mm futhi ukujiya kodonga bungaphansi kuka-0.25mm. Ukugoqa okubandayo kunokunemba okuphezulu kunokulinganisa okushisayo.

Yenziwe ngensimbi yekhwalithi ephezulu ye-carbon efana no-10, 20, 30, 35 kanye no-45, insimbi yesakhiwo esine-alloy ephansi efana ne-16Mn ne-5mnv, noma i-alloy steel efana ne-40Cr, 30CrMnSi, 45Mn2 kanye ne-40MnB. 10. Amapayipi angenamthungo enziwe ngensimbi enekhabhoni ephansi njengangama-20 asetshenziswa kakhulu kumapayipi okudlulisa uketshezi. Amapayipi angenamthungo enziwe ngensimbi ye-carbon steel ephakathi njengo-45 no-40Cr asetshenziselwa ukwakha izingxenye zemishini, njengezingxenye ezigxilile zezimoto nogandaganda. Ngokuvamile, ukuhlolwa kwamandla kanye nokunciphisa kwepayipi lensimbi engenamthungo kuzoqinisekiswa. Amapayipi ensimbi agingqelwe ashisayo azolethwa esimweni esishisayo sokuginqika noma esimweni sokwelashwa kokushisa; Ukugoqa okubandayo kulethwa esimweni sokwelashwa ngokushisa.

Isetshenziselwa ukukhiqiza zonke izinhlobo zama-boilers anengcindezi ephansi naphakathi, amapayipi esitimu ashisa kakhulu, amapayipi amanzi abilayo, amapayipi odonga lwamanzi kanye namapayipi esitimu ashisa kakhulu, amapayipi amakhulu entuthu, amapayipi amancane entuthu kanye namapayipi esitini esinama-arch ama-boilers esitimela. Ipayipi lensimbi eligoqiwe elishisayo noma elibandayo elenziwe ngensimbi yesakhiwo sekhabhoni ephezulu. Ikakhulukazi yenziwe ngensimbi engu-10 no-20. Ngaphezu kokuqinisekisa ukwakheka kwamakhemikhali kanye nezakhiwo zemishini, kuzokwenziwa ukuhlolwa kwe-hydrostatic, crimping, flaring, flattening nokunye. I-Hot rolling izolethwa esimweni sokushisa esishisayo, futhi ukugoqa okubandayo (ukudayela) kuzolethwa esimweni sokwelashwa kokushisa.

Isetshenziswa kakhulu ukwenza insimbi yesakhiwo sekhabhoni yekhwalithi ephezulu, insimbi yesakhiwo sealloy kanye namapayipi ensimbi angenamthungo angangeni ekushiseni amapayipi okubhayela esitimu anomfutho omkhulu nangaphezulu. Lawa mapayipi ama-boiler ngokuvamile asebenza ngaphansi kokushisa okuphezulu nokucindezela okukhulu. Amapayipi azophinde afakwe i-oxidation kanye nokugqwala ngaphansi kwesenzo segesi yokushisa ephezulu yokushisa nomusi. Ngakho-ke, amapayipi ensimbi adingeka ukuba abe namandla ahlala njalo kanye nokumelana okuphezulu kwe-oxidation, Amabanga ensimbi amukelwayo yilezi: izinga eliphezulu le-carbon structural steel, futhi amamaki ensimbi angama-20g, 20mng no-25mng; Ingxubevange amamaki steel kwesakhiwo: 15mog, 20mog, 12crmog, 15CrMoG, 12CR2MOG, 12crmovg, 12Cr3MoVSiTiB, njll; Ngokungeziwe ekuqinisekiseni ukwakheka kwamakhemikhali kanye nezakhiwo zemishini, i-1Cr18Ni9 kanye ne-1cr18ni11nb yamashubhu kabhayela wokucindezela okuphezulu avame ukusetshenziswa kunsimbi ekwazi ukumelana nokushisa azoba ngaphansi kokuhlolwa kwe-hydrostatic, ukuvutha kanye nokuhlolwa kokucaba ngakunye ngakunye. Amapayipi ensimbi azolethwa esesimweni esiphathwa ngokushisa. Ngaphezu kwalokho, kunezidingo ezithile ze-microstructure, usayizi wokusanhlamvu kanye nesendlalelo se-decarburization yepayipi yensimbi eqediwe.

Ukuze uhlole ukwakheka kwamatshe angaphansi komhlaba, amanzi angaphansi komhlaba, uwoyela, igesi yemvelo kanye nemithombo yamaminerali, imishini yokumba isetshenziselwa ukumba imithombo. Ukuxhashazwa kukawoyela negesi akunakuhlukaniswa nokumba. Amapayipi ensimbi angenamthungo okumba i-geological drilling kanye nokumba uwoyela ayizinto ezisetshenziswa kakhulu zokumba, ikakhulukazi okuhlanganisa ipayipi langaphandle eliwumgogodla, ipayipi elingaphakathi elingaphakathi, i-casing, ipayipi lokubhoboza, njll. Njengoba ipayipi lokubhola lidinga ukusebenza ekujuleni kwamamitha ayizinkulungwane ezimbalwa, ukusebenza izimo ziyinkimbinkimbi ngokwedlulele, ipayipi lokubhoboza lithwala imiphumela yengcindezi yokushuba, ukucindezelwa, ukugoba, ukugoqa kanye nomthwalo womthelela ongalingani, futhi ligqokwa udaka namatshe. Ngakho-ke, ipayipi kufanele libe namandla anele, ukuqina, ukumelana nokugqokwa kanye nokuba namandla okushayisana, Insimbi yepayipi lensimbi imelwa yi-"DZ" (isiqalo se-Geological Chinese Pinyin) kanye nenombolo ezomela iphuzu lokuvunwa kwensimbi. Amabanga ensimbi asetshenziswa kakhulu yi-45mnb kanye ne-50Mn ye-dz45; 40Mn2 kanye no-40mn2si we-dz50; I-40mn2mo kanye ne-40mnvb ye-dz55; 40mnmob ye-DZ60 kanye ne-27mnmovb ye-dz65. Amapayipi ensimbi alethwa esimweni esiphethwe ukushisa.

Amashubhu angenamthungo wamashubhu esithandweni somlilo, amashubhu okushintsha ukushisa namapayipi ezindaweni zokuhluza i-petroleum. Ivamise ukwenziwa nge-carbon steel yekhwalithi ephezulu (10, 20), i-alloy steel (12CrMo, 15CrMo), insimbi engashisi (12cr2mo, 15cr5mo) nensimbi engagqwali (1Cr18Ni9, 1Cr18Ni9Ti). Ngokungeziwe ekwakhekeni kwamakhemikhali kanye nezakhiwo ezahlukahlukene zemishini yepayipi lensimbi, kuyadingeka futhi ukuthi kuqinisekiswe i-hydrostatic, flattening, flaring nezinye izivivinyo, kanye nekhwalithi ephezulu kanye nokuhlolwa okungabhubhisi. Amapayipi ensimbi azolethwa ngaphansi kokwelashwa ngokushisa.

Ipayipi lensimbi engagqwali: zonke izinhlobo zamapayipi ensimbi engagqwali ashisayo agoqelwe nabandayo asetshenziswa kakhulu kumapayipi emishini kaphethiloli namakhemikhali kanye nezingxenye zesakhiwo sensimbi engagqwali ngezinjongo ezahlukahlukene. Ngokungeziwe ekuqinisekiseni ukwakheka kwamakhemikhali kanye nezakhiwo zemishini, wonke amapayipi ensimbi asetshenziselwa ukuthwala ingcindezi yoketshezi azofaneleka ekuhlolweni kwe-hydrostatic. Amapayipi ensimbi akhethekile ahlukahlukene azoqinisekiswa ngokwemibandela ebekiwe.

Ngokwezibalo ezingaphelele, kunamabhizinisi okukhiqiza amapayipi angenamthungo angaphezu kuka-240 kanye namayunithi angamapayipi ensimbi angenamthungo angaphezu kuka-250 eShayina, anomthamo wonyaka wamathani angaphezu kwezigidi ezingu-4.5. Ngokwe-caliber< φ 76, ibalwa ku-35%< φ 159-650, ibalwa ku-25%. Mayelana nezinhlobonhlobo, amathani ayizigidi eziyi-1.9 zamapayipi enhloso ejwayelekile, alinganiselwa ku-54%; amathani angama-760000 wamapayipi kawoyela, alinganiselwa ku-5.7%; amathani ayi-150000 wepropu ye-hydraulic kanye nepayipi elinembile, elibalelwa ku-4.3%; Ipayipi elingagqwali, ipayipi elithwele kanye nepayipi lemoto amathani angu-50000, okubalelwa ku-1.4%.

I-billet ithunyelwa esithandweni ukuze kushiswe ekushiseni okungaba ngu-1200 degrees Celsius. Uphethiloli yi-hydrogen noma i-acetylene. Ukulawulwa kwezinga lokushisa esithandweni kuyinkinga eyinhloko. Ngemuva kokuthi i-tube billet eyindilinga ikhishwe esithandweni, kufanele ibhobozwe ngombhobho wokucindezela. Ngokuvamile, umbhobozi ovame kakhulu umbhobozi we-conical roll. Lesi sibhobosi sisebenza kahle kakhulu ekukhiqizeni, ikhwalithi yomkhiqizo omuhle, ukunwetshwa okukhulu kwezibhobo futhi singagqoka amamaki ensimbi ahlukahlukene. Ngemuva kokubhobozwa, ishubhu eliyindilinga elingenalutho ligoqwa ngokulandelana ngama-roll amathathu awela, ukugoqa okuqhubekayo noma ukukhipha. Ngemuva kwe-extrusion, susa ipayipi ukuze ulinganise. Umshini wokulinganisa uzungezisa kumbungu wensimbi ngesivinini esikhulu ngokusebenzisa i-conical drill ukuze wakhe ipayipi lensimbi. Ububanzi bangaphakathi bepayipi lensimbi bunqunywa ubude be-diameter yangaphandle yebhithi yomshini wokulinganisa. Ngemva kokulinganisa, ipayipi lensimbi lingena embhoshongweni wokupholisa futhi lipholiswe ngesifutho samanzi. Ngemuva kokupholisa, ipayipi lensimbi lizoqondiswa. Ngemva kokuqondisa, ipayipi lensimbi lithunyelwa kumtshina wensimbi (noma ukuhlolwa kwe-hydrostatic) ngebhande lokudlulisa ukuze kutholwe amaphutha angaphakathi. Uma kukhona ukuqhekeka, ama-bubbles nezinye izinkinga ngaphakathi kwepayipi lensimbi, zizotholwa. Amapayipi ensimbi kufanele akhethwe ngokuqinile ngesandla ngemuva kokuhlolwa kwekhwalithi. Ngemuva kokuhlolwa kwepayipi lensimbi, inombolo, ukucaciswa, inombolo ye-batch yokukhiqiza, njll. izofafazwa ngopende. Futhi waphakanyiselwa endlini yokugcina izimpahla by crane.