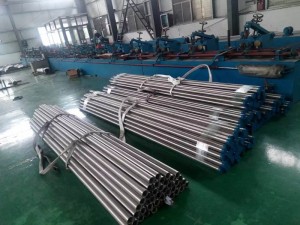

China 27SiMn umkhiqizi wepayipi lensimbi ye-hydraulic

27SiMn ipayipi lensimbi engenamthungo, okungukuthi i-silicon manganese ipayipi lensimbi engenamthungo, ingenye yezinto zepayipi lensimbi engenamthungo, futhi okuqukethwe kwekhabhoni kuphakathi kuka-0.24-0.32%. I-SIMN ibhalwe ngokwehlukana ngoba okuqukethwe kwe-silicon manganese ezakhini ezinhlanu (i-carbon C, i-silicon Si, i-manganese Mn, i-phosphorus P, isulfure s) icishe ibe ngu-1.10-1.40%. Ipayipi elingenamthungo le-27SiMn lilungele imboni yamandla, indawo yokubhayela, imboni yamakhemikhali, izesekeli zezimoto nezemikhumbi, njll.

27SiMn, ipayipi le-hydraulic strut. Ikhodi yedijithali ehlanganisiwe: a10272

Okujwayelekile: GB / t17396-2018

Lolu hlobo lwensimbi lunezakhiwo ezingcono kunensimbi engu-30Mn2, ukuqina okuphezulu, ukuqina okubucayi ububanzi obuyi-8 ~ 22mm emanzini, ukuhleleka okuhle, ukuguqulwa kwepulasitiki okubandayo okuphakathi kanye nokushisela; Ngaphezu kwalokho, ukuqina kwensimbi akwehli kakhulu ngesikhathi sokwelashwa kokushisa, kodwa kunamandla amakhulu kakhulu nokumelana nokugqoka, ikakhulukazi lapho amanzi ecima; Kodwa-ke, le nsimbi iyazwela endaweni emhlophe, ukufutheka kwentukuthelo kanye nokuzwela ukushisa ngokweqile ngesikhathi sokwelashwa kokushisa.

Lolu hlobo lwensimbi lusetshenziswa kakhulu esimweni esicishiwe nesifuthekile ukwenza izingxenye ezishisayo zokugxiviza ezidinga ukuqina okuphezulu nokumelana nokugqoka; Ingasetshenziswa futhi ngaphansi kokuhlinzekwa okujwayelekile okujwayelekile noma okushisayo, njengephinikhodi yethrekhi kagandaganda, njll.

Ukusetshenziswa kwepayipi elingenamthungo le-SIMN engama-27 kanye nepayipi elijwayelekile lensimbi

27SiMn ipayipi lensimbi elingenamthungo

27SiMn ipayipi lensimbi elingenamthungo

1. Ipayipi lensimbi engenamthungo yoketshezi: GB / t8163-2018

2. Ipayipi lensimbi engenamthungo kubhayela: GB / t3087-2018

3. Ipayipi elicindezelayo elingenamthungo kubhayela: GB / t5310-2018 (ST45.8 - uhlobo III)

4. Ipayipi lensimbi engenamthungo ephezulu yemishini yamakhemikhali: GB / t6479-2018

5. Ipayipi lensimbi elingenamthungo lokumba i-geological: yb235-70

6. Ipayipi lensimbi elingenamthungo lokumba uwoyela: yb528-65

7. Ipayipi lensimbi elingenamthungo lokuqhekeka kwe-petroleum: GB / t9948-2018

8. Ipayipi elikhethekile elingenamthungo lekhola yokumba i-petroleum: yb691-70

9. Ipayipi lensimbi elingenamthungo le-axle shaft yemoto: GB / t3088-2018

10. Ipayipi lensimbi engenamthungo yemikhumbi: GB / t5312-2018

11. Ipayipi lensimbi elibandayo elidonsa elibandayo eligoqelwe ngokunemba: GB / t3639-2018

12. Ipayipi lensimbi elingenamthungo le-hydraulic prop: GB / t17396-2018

Izakhiwo zikamshini zepayipi lensimbi elingenamthungo elingu-27SiMn

Amandla e-Tensile σ b (MPa): ≥980

isivuno amandla σ s (MPa): ≥835

Ubude δ 5/(%): ≥12

Ukwehliswa kwendawo ψ/(%): ≥40

Amandla okumunca anomthelela (inani lomthelela) (aku2 / J): ≥ 39

Wonke amapayipi ensimbi angenamthungo kufanele ahlolelwe izakhiwo zemishini. Izindlela zokuhlola zezakhiwo zemishini zihlukaniswe ikakhulukazi izigaba ezimbili: ukuhlolwa kwe-tensile kanye nokuhlolwa kokuqina.

Ukuhlolwa kwe-Tensile ukwenza ipayipi lensimbi elingenamthungo libe isampula, ukudonsa isampula ukuze liphuke emshinini wokuhlola oqinile, bese ukala isici esisodwa noma ezimbalwa zomshini. Ngokuvamile, kulinganiswa amandla aqinile kuphela, amandla esivuno, ubude ngemva kokuphuka nokuncipha kwendawo.

Ukuhlolwa kokuqina ukucindezela kancane kancane i-indenter eqinile endaweni yesampula ngokuya ngezimo ezishiwo, bese uhlola ukujula kokuhlehlisa noma usayizi, ukuze kutholwe ubulukhuni bento.

I-machinability enhle, ipulasitiki ye-deformation ebandayo ephakathi kanye nokushisela; Ngaphezu kwalokho, ukuqina kwensimbi akwehli kakhulu ngesikhathi sokwelashwa kokushisa, kodwa kunamandla amakhulu kakhulu nokumelana nokugqoka, ikakhulukazi lapho amanzi ecima; Kodwa-ke, le nsimbi iyazwela endaweni emhlophe, ukufutheka nokuzwela ukushisa ngokweqile ngesikhathi sokwelashwa kokushisa.

Izinyathelo zokuqapha ukuhlolwa kokukhulisa okuphezulu kwepayipi lensimbi engenamthungo

Izinyathelo zokuqapha zokuhlolwa kokukhuliswa okuphezulu kwepayipi lensimbi engenamthungo ikakhulukazi kufaka phakathi amaphuzu alandelayo:

1. Ukujula kanye nezinga le-surface decarburization.

2. Ubude nokujula kweziphambeko eziginqikayo, umgodi wokushwabana, ukuhlukaniswa okumaphakathi kwekhabhoni nesibabule.

3. Ukusatshalaliswa kwe-ferrite ne-pearlite kupayipi lensimbi engenamthungo.

4. Okunye ukukhubazeka kwe-microstructure, kanye nosayizi wokusanhlamvu, amapayipi angenamthungo amaholoholo kanye nokuqukethwe okufakwayo.