Ukuthengiswa okukhona kweshubhu elikhulu elingunxande

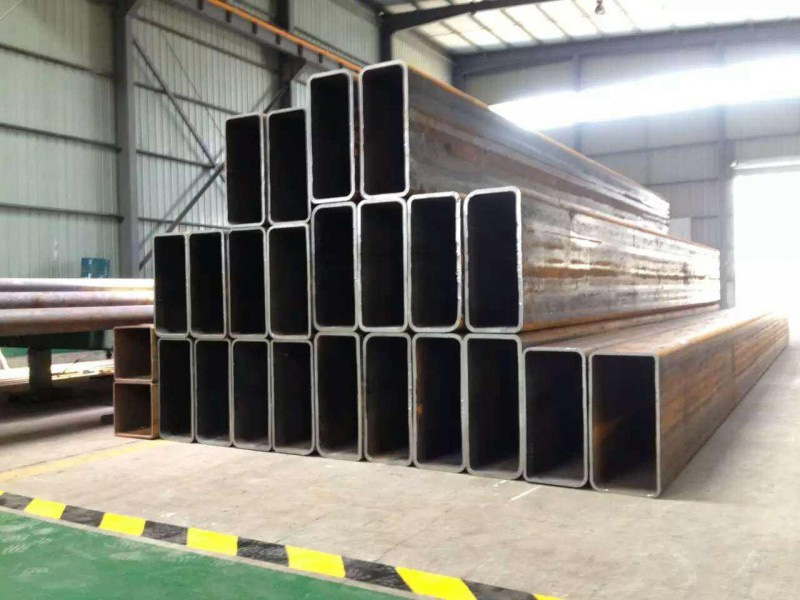

Ipayipi eliyisikwele elinobubanzi obukhulu, elinengxenye engenalutho, lisetshenziswa kabanzi njengepayipi lokudlulisa uketshezi

Njengamapayipi okuthutha uwoyela, igesi yemvelo, igesi, amanzi nezinye izinto eziqinile. Uma kuqhathaniswa nensimbi eqinile njengensimbi eyindilinga, ipayipi lensimbi inokugoba okufanayo namandla okugoqa kanye nesisindo esilula. Kuyinsimbi yesigaba sezomnotho. Isetshenziswa kakhulu ekwenzeni izingxenye zesakhiwo kanye nezingxenye zemishini, njengepayipi lokubhoboza uwoyela, umshini wokuhambisa imoto, uhlaka lwamabhayisikili kanye nesikafula sensimbi esisetshenziswa ekwakheni. Ukukhiqiza izingxenye zendandatho ngamapayipi ensimbi kungathuthukisa ukusetshenziswa kwezinto, kube lula izinqubo zokukhiqiza, futhi konge izinto zokwakha namahora okucubungula, njengamaringi okugingqa, imikhono kaJack, njll. Amapayipi ensimbi asetshenziswe kabanzi ekukhiqizeni. Ipayipi lensimbi liphinde libe yinto esemqoka yazo zonke izinhlobo zezikhali ezijwayelekile. Isibhamu kanye nomgqomo kufanele kwenziwe ngepayipi lensimbi. Ipayipi lensimbi lingahlukaniswa libe yipayipi eliyindilinga kanye nepayipi elimise okukhethekile ngokuya ngendawo ehlukene ye-cross-sectional kanye nokuma. Ngenxa yokuthi indawo eyindilinga inkulu kakhulu ngaphansi kwesimo somjikelezo olinganayo, uketshezi oluningi lungathuthwa ngepayipi eliyindilinga. Ukwengeza, lapho isigaba sendandatho singaphansi kokucindezela kwe-radial yangaphakathi noma yangaphandle, amandla afana kakhulu. Ngakho-ke, amapayipi amaningi ensimbi angamapayipi ayindilinga. Nokho, ipayipi eliyindilinga nalo linemikhawulo ethile. Isibonelo, ngaphansi kwesimo sokugoba indiza, amandla okugoba wepayipi eliyindilinga awanamandla njengalawo wesikwele kanye nepayipi elingunxande. Amapayipi ayisikwele nawonxande avame ukusetshenziswa ohlakeni lwemishini ethile yezolimo namathuluzi nefenisha yensimbi neyokhuni. Amapayipi ensimbi anobunjwa obukhethekile obunye ubujamo besigaba nawo ayadingeka ngokwezinjongo ezahlukene.

1. Ishubhu yesikwele esikhulu sobubanzi besakhiwo (i-GB / T8162-1999) iyishubhu yesikwele esikhulu sobubanzi besakhiwo esijwayelekile kanye nesakhiwo semishini.

2. Ishubhu yesikwele esiwububanzi obukhulu bokuthutha uketshezi (GB / t8163-1999) iyishubhu yesikwele esikhulu esivamile esisetshenziselwa ukuthutha amanzi, uwoyela, igesi nolunye uketshezi.

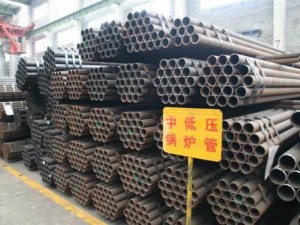

3. Amashubhu ayisikwele amakhulu obubanzi obubanzi be-boiler yengcindezi ephansi naphakathi (GB3087-1999) ayinsimbi yekhwalithi ephezulu ye-carbon structural iron hot-rolled and cold drawn (rongiwe) amashubhu ayisikwele amakhulu amakhulu okukhiqiza amashubhu esitimu esishisa kakhulu, abilayo amashubhu amanzi amabhoyela anengcindezi ephansi naphakathi. wezakhiwo ezihlukahlukene kanye namashubhu esitimu esishisa kakhulu, amashubhu amakhulu entuthu, amashubhu amancane entuthu kanye namashubhu ezitini eziwu-arch zamabhoyili esitimela.

4.Amashubhu ayisikwele amakhulu amakhulu amabhoyela anengcindezi ephezulu (i-GB5310-1995) ayinsimbi yekhwalithi ephezulu yekhabhoni, insimbi eyingxubevange kanye namashubhu ayisikwele ensimbi anobubanzi obungububanzi obukhulu asetshenziselwa ukwakha indawo yokushisisa yamabhayela amanzi anengcindezi ephezulu nangaphezulu. 5. Umfutho ophakeme wepayipi eliyisikwele elinobubanzi obukhulu (GB6479-2000) lemishini kamanyolo yamakhemikhali iyinsimbi yekhwalithi ephezulu ye-carbon structural ne-alloy steel ububanzi bepayipi eliyisikwele elifanele imishini yamakhemikhali kanye nepayipi elinokushisa okusebenzayo okungu-40 ~ 400 ℃ nokucindezela kokusebenza. 10 ~ 30mA.

6. Amashubhu ayisikwele anobubanzi obukhulu bokuqhekeka kwe-petroleum (gb9948-88) amashubhu ayisikwele amakhulu anobubanzi afanele amashubhu esithandweni somlilo, izinto ezishintsha ukushisa namapayipi ezindaweni zokuhluza uphethiloli.

7. Ipayipi lensimbi lokumba i-geological drilling (yb235-70) yipayipi lensimbi elisetshenziswa umnyango we-geological for core drilling. Ngokwenhloso, ingahlukaniswa ngepayipi lokubhoboza, ikhola yokubhoboza, ipayipi eliwumgogodla, i-casing kanye nepayipi le-sedimentation.

8. Ishubhu yesikwele esiwububanzi obukhulu (gb3423-82) yokumba umnyombo wedayimane iyishubhu enkulu yesikwele enobubanzi bepayipi lokubhoboza, induku ewumgogodla kanye nekesi esetshenziselwa ukumba umnyombo wedayimane.

9.Ipayipi lokumba uwoyela (yb528-65) ipayipi lesikwele esingububanzi obukhulu elisetshenziselwa ukujiya kwangaphakathi noma kwangaphandle kuzo zombili iziphetho zokumba uwoyela. Ipayipi lensimbi lihlukaniswe ngocingo oluphendukayo nocingo olungajiki. Ipayipi lentambo ephendukayo lixhunywe nejoyinti, futhi ipayipi lentambo elingajiki lixhunywe nejoyinti yethuluzi ngokushisela izinqe.

10.Insimbi yensimbi ye-carbon steel enobubanzi obukhulu bepayipi eliyisikwele (gb5213-85) iyinsimbi yensimbi enobubanzi obukhulu bepayipi eliyisikwele lokukhiqiza uhlelo lwamapayipi okucindezela ekilasi I, uhlelo lwepayipi lomfutho wesigaba II, ibhayela kanye ne-superheater. Izinga lokushisa elisebenzayo le-carbon steel-diameter square tube wall akufanele lidlule i-450 ℃, futhi izinga lokushisa elisebenzayo lensimbi yensimbi enobubanzi obukhulu be-square tube wall lizodlula ama-450 ℃.

11. Ishubhu yesikwele esiwububanzi obukhulu bomkhono we-axle wemoto (gb3088-82) iyishubhu yesikwele esikhulu esigoqelwe ngokushisayo eyenziwe ngensimbi yekhwalithi ephezulu ye-carbon structural steel kanye nensimbi yesakhiwo ye-alloy yomkhono we-axle wemoto kanye nendlu ye-asi yokushayela.

12. Ipayipi likawoyela elinomfutho ophezulu wenjini kadizili (gb3093-2002) iyipayipi lesikwele elingububanzi obubandayo elidonswayo lokukhiqiza ipayipi elinengcindezi ephezulu lesistimu yomjovo wenjini kadizili.

13. Ukunemba okungaphakathi kobubanzi bobubanzi obukhulu beshubhu yesikwele yomphongolo we-hydraulic kanye ne-pneumatic cylinder (GB8713-88) iyishubhu eliyisikwele elidonsa ngendlela ebandayo noma elibandayo eliwububanzi obuyindilinga elinobubanzi obunemba obungaphakathi bokukhiqiza umphongolo wesilinda womoya kanye ne-pneumatic.

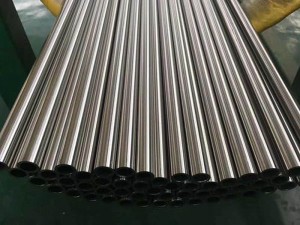

14.Ishubhu eliyisikwele elibandayo elidonsayo noma eligoqeke elibandayo eliwububanzi obukhulu obukhulu (GB3639-2000) iyishubhu yesikwele edonsayo noma ebandayo egoqekayo enobubanzi obuphezulu obunembayo kanye nesiphetho esihle sokwakheka kwemishini kanye nemishini ye-hydraulic. Ukukhetha ukunemba kweshubhu yesikwele enobubanzi obukhulu ukwenza ukwakheka kwemishini noma okokusebenza okudonsa amanzi kungasindisa kakhulu amahora omshini, kuthuthukise ukusetshenziswa kwezinto futhi kuthuthukise ikhwalithi yomkhiqizo.

15. Ipayipi lesikwele lensimbi engagqwali eliwububanzi obukhulu besakhiwo (i-GB / T14975-2002) iyipayipi eliyisikwele elishisayo (elinwetshiwe, elinwetshiwe) nelibandayo (eligoqiwe) elenziwe ngensimbi engagqwali yamapayipi angagqwali, izingxenye zesakhiwo kanye izingxenye ezisetshenziswa kabanzi kumakhemikhali, uphethiloli, izindwangu ezilula, ezokwelashwa, zokudla, imishini nezinye izimboni.

16. Insimbi engagqwali ubukhulu beshubhu yesikwele yokuthutha uketshezi (i-GB / T14976-2002) iyishubhu eyisikwele eshisayo eshisayo (enwetshiwe, enwetshiwe) futhi ebandayo (egoqiwe) enobubanzi obukhulu eyenziwe ngensimbi engagqwali yokuthutha uketshezi.

17.Ishubhu yesikwele enomumo okhethekile wobubanzi obukhulu yigama elijwayelekile leshubhu yesikwele enobubanzi obunye nezinye izimo zesigaba ngaphandle kweshubhu eliyindilinga. Ngokwesimo esihlukile nobukhulu besigaba sepayipi lensimbi, lingahlukaniswa libe yipayipi eliyisikwele elinobubanzi obukhethekile obunobubanzi obulinganayo obulingana nodonga (ikhodi D), ipayipi eliyisikwele elimise okukhethekile elinobubanzi obuhlukene obunodonga oluhlukene (ikhodi BD) kanye nepayipi lensimbi elimise okukhethekile elingenamthungo elinobubanzi obuguquguqukayo (ikhodi BJ). Amashubhu angama-rectangular anomumo okhethekile anobubanzi obukhulu asetshenziswa kakhulu ezingxenyeni ezahlukahlukene zesakhiwo, amathuluzi nezingxenye zemishini. Uma kuqhathaniswa nepayipi eliyindilinga, ipayipi elimise okukhethekile ngokuvamile linesikhathi esikhudlwana se-inertia kanye ne-modulus yesigaba, futhi linokumelana nokugoba okukhulu nokuqina, okunganciphisa kakhulu isisindo sesakhiwo futhi yonge insimbi.

Amaphutha amaningi e-square tube abangelwa ukubhobozwa, ngakho-ke inqubo yokudlulisa amandla yeshubhu lesikwele elingenalutho iyinqubo eyinhloko yokukhiqiza ishubhu yesikwele. Ubunzima obukhulu bokubhobozwa kwe-alloy ephezulu bulele ekusebenzeni okuphansi kokubhoboza. Ukuze uqinisekise ikhwalithi, kuyadingeka ukukhetha ngokunengqondo imingcele ye-deformation ye-perforation. Ukucindezelwa okuncane kuzodala ukungazinzi enqubweni yokubhoboza, ngakho-ke lapho ukucindezela okubalulekile kukuncane, ipulaki kufanele ibe ngaphambili, futhi ukucindezela kuvame ukusetha cishe ku-7%, ngaphandle kwalokho ngeke kulume, noma kwandise ukunyakaza noma uthole. wanamathela ngaphambili. Ukwenyuka kokucindezelwa phambi kwepulaki nakho kuzokwakha imbobo yembobo futhi kucwilise amaphutha emsindweni. Ngakho-ke, uma ufuna ukuxazulula inkinga yesevisi yamakhasimende, ipayipi elingenalutho kufanele ligxile, futhi ukujula okungenalutho kwe-centering kufanele kuqhathaniswe ngokuvumelana namanye amamaki ensimbi. Ngakho-ke, uhlelo lokushisa yizinga lokushisa eliphumayo kanye nezidingo zekhwalithi yokushisa. Izinga lokushisa lincike kakhulu ekusebenzeni kokushisa kanye nesistimu yokushisa. I-elliptical coefficient encane ngokuvamile izothuthukisa ikhwalithi ye-capillary futhi inciphise ukuguquguquka okuphambene. Kodwa-ke, i-ellipse coefficient incane kakhulu, okuzodala ubunzima bokuzungezisa izingcezu, futhi kuholele nasekugqokeni kwepuleti lomhlahlandlela, okulula ukubangela amaphutha ebusweni. Ngakho-ke, ukuguga kwepuleti lomhlahlandlela kufanele kuhlolwe ngokujwayelekile lapho umkhumbi ubopha ipayipi eliyisikwele. Uma isitholakele, kufanele ishintshwe ngokushesha. Izinga le-ellipse kufanele lilawulwe ngaphakathi kwebanga lika-1.07-1.08. Kuthinta ukusebenza okuvamile kwezinqubo ezilandelayo, kanye nenqubo eyinhloko yokushisa i-square tube tube blank, ebuye ibe nomthelela omkhulu kwikhwalithi yemikhiqizo eqediwe.