I-A106grb isitokwe somkhiqizi wamapayipi ensimbi angenamthungo

Ipayipi lensimbi linengxenye engenalutho futhi ubude balo bukhulu kakhulu kunobubanzi noma umjikelezo wensimbi. Ngokusho komumo wesigaba, ihlukaniswe ngamapayipi ensimbi ayindilinga, ayizikwele, angama-rectangular futhi amise okukhethekile; Ngokusho kwempahla, ihlukaniswe ngepayipi lensimbi yesakhiwo se-carbon, ipayipi yensimbi ephansi ye-alloy, ipayipi yensimbi ye-alloy kanye nepayipi yensimbi eyinhlanganisela; Ihlukaniswe ngamapayipi ensimbi epayipi lokudlulisa, isakhiwo sobunjiniyela, izinto ezishisayo, imboni ye-petrochemical, ukukhiqizwa kwemishini, ukumba i-geological, imishini yokucindezela okuphezulu, njll; Ngokwenqubo yokukhiqiza, ihlukaniswe yaba ipayipi lensimbi engenamthungo kanye nepayipi lensimbi elishiselwe. Ipayipi lensimbi elingenamthungo lihlukaniswe libe eligoqayo elishisayo nelibandayo (umdwebo), kanti ipayipi lensimbi elishiselwe lihlukaniswe libe ipayipi lensimbi elinomthungo oqondile kanye nepayipi lensimbi elivunguzayo.

Ipayipi lensimbi alisetshenziselwa kuphela ukudlulisa okuqinile okuwuketshezi kanye nempuphu, ukushintshanisa amandla okushisa, ukukhiqiza izingxenye zemishini neziqukathi, kodwa futhi nensimbi yezomnotho. Ukusebenzisa ipayipi lensimbi ukwenza igridi yesakhiwo sesakhiwo, insika kanye nokusekelwa kwemishini kunganciphisa isisindo, konga insimbi ngo-20 ~ 40%, futhi kuqashelwe ukwakhiwa kwezimboni kanye nemishini. Ukukhiqiza Amabhuloho Omgwaqo Omkhulu ngamapayipi ensimbi akukwazi nje ukulondoloza insimbi nokwenza lula ukwakhiwa, kodwa futhi kunciphise kakhulu indawo yokumboza okuvikelayo futhi kulondoloze izindleko zokutshala izimali nezokulungisa.

Ngendlela yokukhiqiza

Amapayipi ensimbi angahlukaniswa abe izigaba ezimbili ngokwezindlela zokukhiqiza: amapayipi ensimbi angenamthungo namapayipi ensimbi ashiselwe. Amapayipi ensimbi ashiselwe abizwa ngokuthi amapayipi ashiselwe ngamafuphi.

1. Ipayipi lensimbi elingenamthungo lingahlukaniswa libe ipayipi eligoqiwe elingenamthungo elishisayo, ipayipi elidonsayo elibandayo, ipayipi lensimbi elinembayo, ipayipi elinwetshiwe elishisayo, ipayipi elibandayo eliphothayo kanye nepayipi elikhishwe ngokwendlela yokukhiqiza.

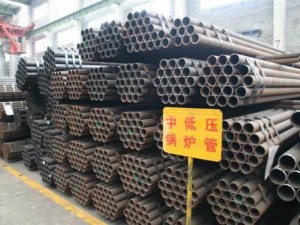

Izinqwaba zamapayipi ensimbi

Ipayipi lensimbi engenamthungo lenziwe ngensimbi ephezulu ye-carbon steel noma i-alloy steel, engahlukaniswa ibe yi-hot rolling kanye ne-cold rolling (umdwebo).

2.Ipayipi lensimbi elihlanganisiwe lihlukaniswe ipayipi elishiselwe esithandweni, ipayipi kagesi (ukumelana ne-welding) kanye nepayipi elizenzakalelayo le-arc elishiselwe ngenxa yezinqubo ezahlukene zokushisela. Ngenxa yamafomu e-welding ahlukene, ihlukaniswe yaba ipayipi elihlanganisiwe le-seam kanye nepayipi elihlanganisiwe elivunguzayo. Ngenxa yokuma kwayo kokuphela, ihlukaniswe yaba ipayipi eliyindilinga elishiselwe kanye nepayipi elihlanganisiwe elikhethekile (isikwele, eliyisicaba, njll.).

Ipayipi lensimbi elishiselwe lenziwe ngepuleti lensimbi eligoqiwe elishiselwe ngokuhlanganyela kwezinqe noma umthungo ovunguzayo. Ngokwendlela yokukhiqiza, iphinde ihlukaniswe yaba ipayipi lensimbi elishiselwe ukudlulisa uketshezi olunomfutho ophansi, ipayipi lensimbi elivunguzayo, ipayipi lensimbi eligoqiwe eligoqiwe, ipayipi lensimbi elishiselwe, njll. Ipayipi lensimbi elingenamthungo lingasetshenziselwa amapayipi oketshezi negesi ezimbonini ezahlukene. Amapayipi ashiselwe angasetshenziselwa amapayipi amanzi, amapayipi egesi, amapayipi okufudumeza, amapayipi kagesi, njll.

Ngezinto ezibonakalayo

Ipayipi lensimbi lingahlukaniswa libe yiphayiphi lekhabhoni, ipayipi lengxubevange, ipayipi lensimbi engagqwali, njll. ngokuya ngezinto zamapayipi (okungukuthi ibanga lensimbi).

Ipayipi lekhabhoni lingahlukaniswa libe ipayipi elivamile le-carbon steel kanye nepayipi lekhwalithi ephezulu ye-carbon structural.

Ipayipi ye-alloy ingahlukaniswa: ipayipi le-alloy eliphansi, ipayipi lesakhiwo se-alloy, ipayipi ye-alloy ephezulu kanye nepayipi lamandla aphezulu. Ipayipi elinophawu, ukushisa kanye nepayipi elingagqwali elimelana ne-asidi, i-alloy enembile (njenge-kovar alloy) ipayipi nepayipi le-superalloy, njll.

Ipayipi lensimbi elishiselwe, elaziwa nangokuthi ipayipi elishiselwe, ipayipi lensimbi elishiselwe ngepuleti lensimbi noma umucu wensimbi ngemuva kokucwiliswa. Ipayipi lensimbi elishiselwe linezinzuzo zenqubo yokukhiqiza elula, ukusebenza kahle kokukhiqiza okuphezulu, izinhlobo eziningi nezincazelo kanye nokutshalwa kwezimali kwemishini encane, kodwa amandla ayo ajwayelekile aphansi kunalawo epayipi lensimbi engenamthungo. Kusukela ngawo-1930s, ngokuthuthuka okusheshayo kokukhiqizwa okuqhubekayo kwe-strip esezingeni eliphezulu kanye nenqubekelaphambili yobuchwepheshe bokushisela nokuhlola, ikhwalithi yokushisela ibilokhu ithuthukiswa ngokuqhubekayo, izinhlobonhlobo kanye nokucaciswa kwamapayipi ensimbi ashiselwe kuye kwanda, namapayipi ensimbi angenamthungo athuthukisiwe. ishintshwe emikhakheni eminingi. Amapayipi ensimbi ashiselwe ahlukaniswe abe ipayipi elihlanganisiwe eliqondile kanye nepayipi elihlanganisiwe elivunguzayo ngokuya ngohlobo lwe-weld.

Ipayipi ehlanganisiwe ye-Longitudinal inezinzuzo zenqubo yokukhiqiza elula, ukusebenza kahle kokukhiqiza okuphezulu, izindleko eziphansi kanye nentuthuko esheshayo. Amandla epayipi elishiselwe okuvunguza ngokuvamile aphakeme kunalawo wepayipi elishiselwe ngokuqondile. Ingakhiqiza ipayipi elishiselwe elinobubanzi bepayipi elikhudlwana elingenalutho eliwumngcingo, kanye nepayipi elishiselwe elinobubanzi bepayipi elihlukene elingenalutho lobubanzi obufanayo. Kodwa-ke, uma kuqhathaniswa nepayipi lomthungo eliqondile elinobude obufanayo, ubude be-weld bukhuphuka ngo-30 ~ 100%, futhi isivinini sokukhiqiza siphansi. Ngakho-ke, ukushisela komthungo oqondile kusetshenziswa kakhulu amapayipi ashiselwe anobubanzi obuncane, futhi ukushisela okuvunguzayo kusetshenziswa kakhulu kumapayipi ashiselwe anobubanzi obukhulu.

Ipayipi lensimbi elishiselwe lokudlulisa uketshezi olunengcindezi ephansi (GB / t3091-2008) yaziwa nangokuthi ipayipi elishiselwe elivamile, elivame ukubizwa ngokuthi ipayipi elimnyama. Kuyipayipi elishiselwe insimbi elisetshenziselwa ukudlulisa amanzi, igesi, umoya, uwoyela, isitimu sokushisisa kanye nolunye uketshezi olujwayelekile olunomfutho ophansi nezinye izinjongo. Ukuqina kodonga lokuxhunywa kwepayipi lensimbi kuhlukaniswe ipayipi elivamile lensimbi kanye nepayipi lensimbi eliqinisiwe; Isiphetho se-nozzle sihlukaniswe ngepayipi lensimbi elingenantambo (ipayipi elibushelelezi) kanye nepayipi lensimbi elinentambo. Ipayipi lensimbi elishiselwe lokudlulisa uketshezi olunomfutho ophansi alisetshenziselwa ngokuqondile ukudluliswa koketshezi, kodwa futhi lisetshenziswa kabanzi njengepayipi langempela lepayipi lensimbi elishiselwe ukuhambisa uketshezi olunomfutho ophansi.

1.Ipayipi lensimbi eliphekiwe elishiselwe ukudlulisa uketshezi olunomfutho ophansi (GB / t3091-2008) yaziwa nangokuthi ipayipi lensimbi eliphekiwe, elivame ukubizwa ngokuthi ipayipi elimhlophe. Kuyipayipi lensimbi elidiphu elishisayo elishiselwe (ukushisela isithando somlilo noma ukushisela ngogesi) elisetshenziselwa ukuhambisa amanzi, igesi, uwoyela womoya, ukushisisa isitimu, ukushisisa amanzi nolunye uketshezi oluvamile olunomfutho ophansi noma ezinye izinjongo. Ukuqina kodonga lokuxhunywa kwepayipi lensimbi kuhlukaniswe ipayipi elivamile lensimbi kanye nepayipi lensimbi eliqinile; Ukuphela komlomo we-nozzle kuhlukaniswe ngepayipi lensimbi elingaxhunywanga kanye nepayipi lensimbi elinentambo. Ukucaciswa kwepayipi lensimbi kuvezwa ngobubanzi obujwayelekile (mm), okuyinani elilinganiselwe lobubanzi bangaphakathi. Kuyisiko ukusebenzisa amayintshi, njengokuthi 1/2, 3/4, 1, 2, njll.

2. Umkhono ojwayelekile we-carbon steel wire (Yb / t5305-2006) iyipayipi lensimbi elisetshenziselwa ukuvikela izintambo kumaphrojekthi wokufaka ugesi njengezakhiwo zezimboni nezomphakathi kanye nokufakwa kwemishini nezinto zokusebenza.

3.Umthungo oqondile wepayipi kagesi oshiselwe (GB / t13793-2008) iyipayipi lensimbi elishisela lalo lihambisana ngobude nepayipi lensimbi. Ngokwesakhiwo esijwayelekile, kuvame ukuhlukaniswa ngamapayipi ensimbi ashiselwe imetric, ipayipi elincanyana elicijile, njll.

4.Ipayipi lensimbi elishiselwe i-Spiral seam elingaphansi kwe-arc elishiselwe (SY / t5037-2000) lokudlulisa uketshezi olucindezelayo iyipayipi lensimbi elivunguzayo elisetshenziselwa ukudlulisa uketshezi olucindezelayo, elithatha ikhoyili yensimbi egoqelwe eshisayo njengepayipi elingenalutho, ngokuvamile ukwakheka kokuvunguza okufudumele kanye nezinhlangothi ezimbili. ukushisela i-arc emanzini. Ipayipi lensimbi linamandla okuthwala ingcindezi kanye nokusebenza okuhle kwe-welding. Ngemuva kokuhlolwa okuqinile okunhlobonhlobo kwesayensi nokuhlolwa, kuphephile futhi kuthembekile ukusetshenziswa. Ipayipi lensimbi linobubanzi obukhulu kanye nokusebenza kahle kokudlulisa okuphezulu, futhi lingasindisa utshalomali ekubekeni amapayipi. Ipayipi lisetshenziselwa kakhulu ukuthutha uwoyela negesi yemvelo.

5.Ipayipi lensimbi elishiselwe i-Spiral seam high-frequency welded (SY / t5038-2000) lokuthuthwa koketshezi olucindezelayo ipayipi lensimbi elishiselwe imvamisa elivunguzayo ukuze kuthuthwe uketshezi olucindezelayo, oluthatha ikhoyili yensimbi egoqelwe eshisayo njengepayipi elingenalutho, ngokuvamile ukwakheka kokuvunguza okufudumele. kanye ne-high-frequency lap welding method. Ipayipi lensimbi linomthamo oqinile wokuthwala ingcindezi kanye nepulasitiki enhle, elungele ukushisela nokucubungula; Ngemuva kokuhlolwa nokuhlolwa okunhlobonhlobo okuqinile nokwesayensi, imodeli yensiza inezinzuzo zokusebenzisa okuphephile nokuthembekile, ububanzi obukhulu bamapayipi ensimbi, ukusebenza kahle kokudlulisela phambili, kanye nokonga ukutshalwa kwezimali ekubekweni kwamapayipi. Isetshenziselwa ikakhulukazi ukubeka amapayipi okuthutha uwoyela, igesi yemvelo, njll.

6. Ipayipi lensimbi elishiselwe i-Spiral seam high-frequency weld for general low-pressure fluid transportation (SY / t5039-2000) ithatha ikhoyili yensimbi egoqelwe eshisayo njengepayipi elingenalutho, ukwakheka okugoqekayo okuvamise ukufudumala, futhi isebenzisa indlela yokushisela i-high-frequency lap ukushisela i-spiral seam. ipayipi lensimbi elishiselwe imvamisa ephezulu yokuthutha uketshezi olunengcindezi ephansi.

7.Ipayipi lensimbi elishiselwe ku-Spiral lenqwaba (SY / t5768-2000) lenziwe ngekhoyili yensimbi egoqelwe eshisayo njengepayipi elingenalutho, ngokuvamile ukwakheka kwe-spiral efudumele, futhi lenziwe nge-arc welding enezinhlangothi ezimbili ezingaphansi kwamanzi noma i-high-frequency welding. Isetshenziselwa ipayipi lensimbi isisekelo inqwaba isakhiwo civil building, wharf, ibhuloho nokunye.